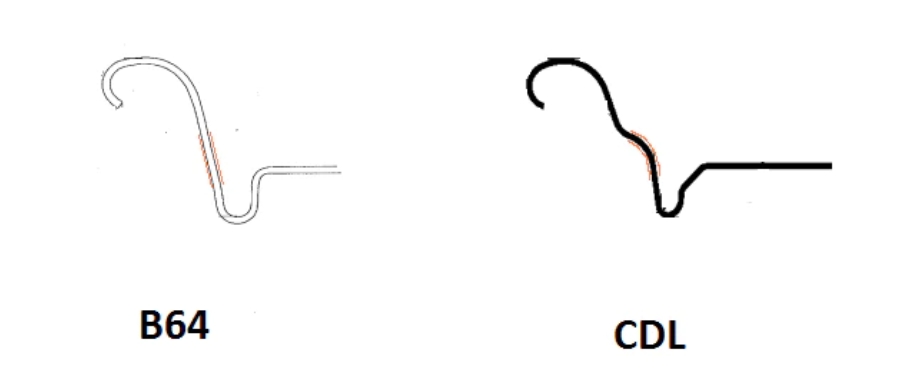

What is the difference between B64 and CDL can ends?

The main difference between CDL and B64 can ends lies in their design and functionality, primarily related to their sealing mechanisms:

CDL (Countersink Double Seam Lid):

Function: CDL is a type of easy-open lid featuring a reverse countersink double seam structure, where the seam portion is inwardly bent and combined with the can end's interior to provide enhanced sealing and leak resistance. This design ensures that beverages remain uncontaminated during long-term storage inside the can.

Distinction: The primary distinction of CDL lies in its double seam structure and strengthened sealing properties. This makes CDL suitable for beverages that require higher hermetic performance.

Applications: CDL is typically used for packaging beverages that require extended shelf life and the preservation of freshness, such as juices, teas, and other oxygen-sensitive liquids. It is also commonly employed for packaging carbonated beverages or those under pressure.

B64 (Beverage Can End 64mm):

Function: B64 is a standard type of easy-open lid with a 64-millimeter diameter, designed to fit standard-sized aluminum beverage cans. It features a conventional aluminum easy-open lid design, suitable for various types of beverages.

Distinction: B64's distinction lies in its universality and compatibility with standard beverage can sizes. Unlike CDL, it does not feature the specialized double seam structure, and its sealing performance may be slightly inferior.

Applications: B64 easy-open lids are among the most common types and find widespread use for packaging various beverage types, including carbonated beverages, fruit juices, beer, energy drinks, and a variety of other beverages. Due to its versatility, it is highly prevalent within the beverage can industry.

In summary, xmbaofeng B64 can ends are standard and commonly used for a wide range of beverages without any specialized sealing features. CDL can ends, on the other hand, have a unique double seam structure that offers enhanced sealing and are used for beverages with specific sealing requirements to ensure extended shelf life and freshness. The choice between the two depends on the specific needs of the beverage being packaged and the desired level of sealing performance.